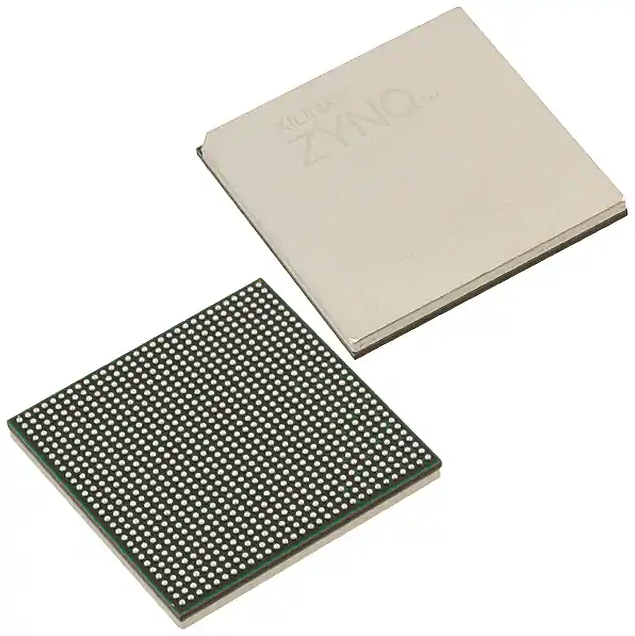

Electronic Components IC Chips Integrated Circuits IC XCZU4EG-2FBVB900E IC SOC CORTEX-A53 900FCBGA

Product Attributes

| TYPE | DESCRIPTION |

| Category | Integrated Circuits (ICs)Embedded |

| Mfr | AMD Xilinx |

| Series | Zynq® UltraScale+™ MPSoC EG |

| Package | Tray |

| Standard Package | 1 |

| Product Status | Active |

| Architecture | MCU, FPGA |

| Core Processor | Quad ARM® Cortex®-A53 MPCore™ with CoreSight™, Dual ARM®Cortex™-R5 with CoreSight™, ARM Mali™-400 MP2 |

| Flash Size | - |

| RAM Size | 256KB |

| Peripherals | DMA, WDT |

| Connectivity | CANbus, EBI/EMI, Ethernet, I²C, MMC/SD/SDIO, SPI, UART/USART, USB OTG |

| Speed | 533MHz, 600MHz, 1.3GHz |

| Primary Attributes | Zynq®UltraScale+™ FPGA, 192K+ Logic Cells |

| Operating Temperature | 0°C ~ 100°C (TJ) |

| Package / Case | 900-BBGA, FCBGA |

| Supplier Device Package | 900-FCBGA (31×31) |

| Number of I/O | 204 |

| Base Product Number | XCZU4 |

How do chip manufacturers view the shortage of core tide?

For the entire automotive electronics industry in a serious shortage of chips and other situations, in the previously held “OFweek Automotive Electronics Technology Online Conference”, OFweek electronic engineering network also specifically interviewed ON Semiconductor, Xilinx and AMS, and other semiconductor manufacturers of professionals and did some discussion.

ON Semiconductor Application Engineer Kai Lijun believes that the automotive chip shortage tide by two aspects, on the one hand, the impact of the new crown pneumonia epidemic in 2020, on the other hand, the consumer electronics market demand is larger, resulting in automotive electronic chip production capacity is limited. Kai Lijun also mentioned that ON Semiconductor is also currently under the influence of shortages, or will be in the third quarter to improve. But for the industry as a whole, fab expansion capacity is slow, in chip supply and demand adjustment is still difficult, so he believes that the lack of core effect will continue for some time.

OFweek electronic engineering network found that the new crown pneumonia epidemic is recognized as one of the reasons for the lack of core. Domestic epidemic control is strong, and social and economic development is in an orderly manner, while foreign countries still need to make every effort to prevent and control the spread of the virus, thus bringing a lot of restrictions to chip manufacturers.

In the opinion of Mao Guanghui, system architect of Xilinx Automotive Electronics, in addition to the impact of the new crown pneumonia, the previous severe situation of international trade has also led to the need for automotive main chips and other devices to go through strict review and preparation process before entering the domestic market through customs, which is more affected. Mao Guanghui believes that ideally, the supply of chips is expected to be eased in the autumn. Of course, it also depends on the continued state of the epidemic and whether the international trade situation can be eased. Mao Guanghui also mentioned that the current chip foundry leading TSMC production capacity load has been full, the entire chip foundry industry capacity oversupply, wanting to restore to normal industry level is still not good judgment.

There is no doubt that the lack of core has become a realistic and serious problem facing the entire semiconductor industry, it is understood that Xilinx started to prepare for the corresponding measures last year, by actively coordinating external resources, as far as possible, the preparation of materials and inventory in advance by customer expectations, for customers to strive for a buffer period of 3-6 months.

Morris Li, FAE manager of Amax Semiconductor, said that the biggest problem facing the automotive electronics industry now is that automotive electronics is different from general electronic semiconductors, it has some special processes, and the backlog of orders from automotive suppliers in the early days due to the suspension of production in the epidemic, now all at once, automotive suppliers will inevitably encounter bottlenecks. In addition, the epidemic before the trade war and other effects, resulting in some manufacturers avoiding subsequent supply constraints on customers, made overbooking (overbooking) behavior, which is also an important reason for the shortage of automotive electronics.

In terms of dealing with the chip shortage crisis, Morris Li mentioned that Emmis Semiconductor has its fabs, especially the one in Austria, which is mainly for the two main applications of automotive and medical. Therefore, from Emmis Semiconductor’s point of view, supply constraints are inevitable, but still in a relatively optimistic state. Morris Li is also more optimistic when it comes to alleviating the shortage of chips in the industry as a whole, as he believes that these problems can be solved one by one and that a balance between supply and demand can be reached soon.