L6205PD013TR 100% New & Original Own Stock integrated circuit High-Performance Clock Buffer Family

Product Attributes

|

EU RoHS |

Compliant with Exemption |

|

ECCN (US) |

EAR99 |

|

Part Status |

Active |

|

HTS |

8542.39.00.01 |

|

SVHC |

Yes |

|

SVHC Exceeds Threshold |

Yes |

|

Automotive |

No |

|

PPAP |

No |

|

Type |

Motor Driver |

|

Motor Type |

Stepper Motor |

|

Process Technology |

DMOS|BCD|Bipolar|CMOS |

|

Control Interface |

PWM |

|

Output Configuration |

Full Bridge |

|

Minimum Operating Supply Voltage (V) |

8 |

|

Operating Supply Voltage (V) |

8 to 52 |

|

Typical Operating Supply Voltage (V) |

48 |

|

Maximum Operating Supply Voltage (V) |

52 |

|

Shutdown Threshold (V) |

6 |

|

Minimum Operating Temperature (°C) |

-40 |

|

Maximum Operating Temperature (°C) |

150 |

|

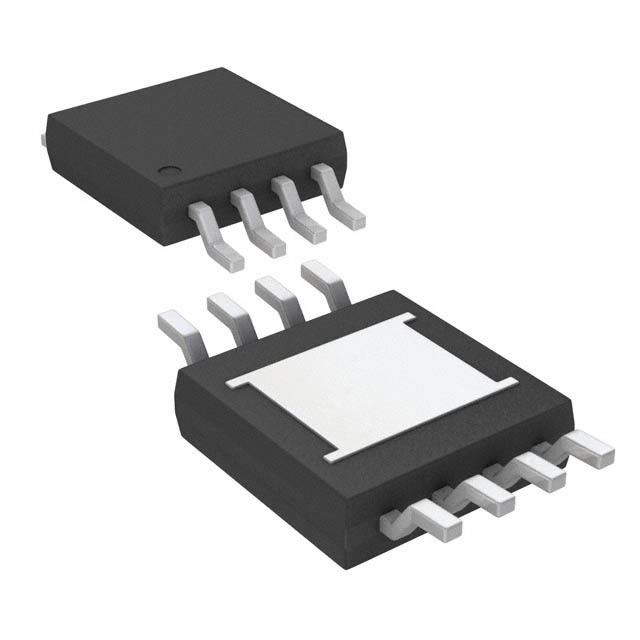

Packaging |

Tape and Reel |

|

Mounting |

Surface Mount |

|

Package Height |

3.3(Max) |

|

Package Width |

11.1(Max) |

|

Package Length |

16(Max) |

|

PCB changed |

20 |

|

Standard Package Name |

SOP |

|

Supplier Package |

PowerSO |

|

Pin Count |

20 |

What is a stepper drive?

The stepper driver is a power amplifier that drives the operation of the stepper motor, which can receive the control signal sent by the controller (PLC/ MCU, etc.) and control the corresponding Angle/step of the stepper motor. The most common control signal is the pulse signal, and the stepper driver receives an effective pulse to control the stepper motor to run one step. The stepper driver with subdivision function can change the inherent step Angle of the stepper motor to achieve greater control accuracy, reduce vibration and increase output torque. In addition to the pulse signal, the stepper driver with bus communication function can also receive the bus signal to control the stepper motor to carry out the corresponding action.

The role of stepper motor driver

Stepper motor driver is a kind of actuator which can convert the electrical pulse signal into angular displacement. When the stepper motor driver receives an electrical pulse signal, it drives its stepper motor to rotate a fixed angular displacement (we call it the "step Angle") in accordance with the direction originally set, and its rotation is run step by step according to a fixed Angle. We can control the displacement of the Angle by controlling the number of pulses sent, so as to achieve the purpose of accurate positioning. At the same time, we can also control the speed and acceleration of the stepper motor by controlling the frequency of its pulse signal, so as to achieve the purpose of speed regulation and positioning. It is widely used in a variety of carving machines, crystal grinding machines, medium-sized CNC machine tools, EEG embroidery machines, packaging machinery, fountains, dispensing machines, cutting and feeding systems, and other large and medium-sized CNC equipment with higher resolution requirements.

The phase number of the stepper motor refers to the number of coil groups inside the stepper motor, commonly used two-phase, three-phase, four-phase, five-phase stepper motors. The number of phases of the motor is different, and the step Angle is different, and the step Angle of the common two-phase stepper motor is 1.8 degrees, the three-phase is 1.2 degrees, and the five-phase is 0.72 degrees. When the stepper motor subdivision driver is not configured, the user mainly relies on the selection of different phase numbers of stepper motors to meet the step Angle requirements. If the subdivision driver is used, the number of phases becomes meaningless, and the user can change the step Angle only by changing the fine fraction on the driver.

The subdivision of the stepper motor driver will produce a qualitative leap in the motor's operating performance, but all this is generated by the driver itself, and has nothing to do with the motor and control system. In use, the only point that the user needs to pay attention to is the change of the step Angle of the stepper motor, which will affect the frequency of the stepping signal issued by the control system, because the step Angle of the stepper motor will be smaller after subdivision, the frequency of the request step signal should be improved accordingly. Take the 1.8-degree stepper motor as an example: the step Angle of the driver in the half-step state is 0.9 degrees, and the step Angle in the ten-step time is 0.18 degrees, so that under the condition of requesting the same motor speed, the frequency of the stepping signal sent by the control system is 5 times that of the half-step operation in the ten-step time.

The accuracy of the ordinary stepper motor is 3~5% of the stepping Angle. The single-step deviation of the stepper motor does not affect the accuracy of the next step, so the accuracy of the stepper motor does not accumulate.