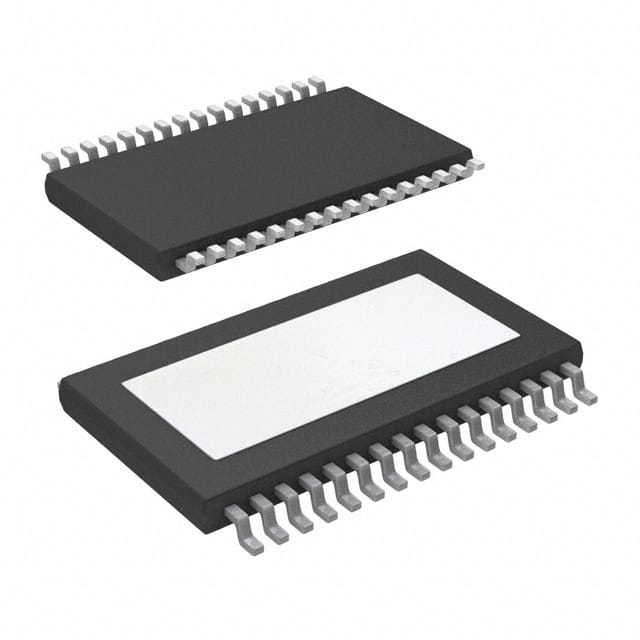

New and original TPA3116D2DADR Integrated circuit IC Chips electronics components

Product Attributes

| TYPE | DESCRIPTION |

| Category | Integrated Circuits (ICs) |

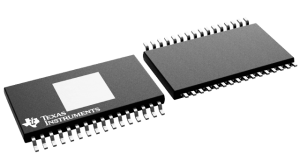

| Mfr | Texas Instruments |

| Series | SpeakerGuard™ |

| Package | Tape & Reel (TR)

Cut Tape (CT) Digi-Reel® |

| SPQ | 2000T&R |

| Product Status | Active |

| Type | Class D |

| Output Type | 2-Channel (Stereo) |

| Max Output Power x Channels @ Load | 50W x 2 @ 4Ohm |

| Voltage - Supply | 4.5V ~ 26V |

| Features | Differential Inputs, Mute, Short-Circuit and Thermal Protection, Shutdown |

| Mounting Type | Surface Mount |

| Operating Temperature | -40°C ~ 85°C (TA) |

| Supplier Device Package | 32-HTSSOP |

| Package / Case | 32-TSSOP (0.240", 6.10mm Width) Exposed Pad |

| Base Product Number | TPA3116 |

In the early days of the semiconductor chip, silicon was not the main character, germanium was. The first transistor was a germanium-based transistor and the first integrated circuit chip was a germanium chip.

The first transistor was invented by Bardeen and Bratton, who invented the bipolar transistor (BJT). The first P/N junction diode was invented by Shockley and, immediately, this junction type designed by Shockley became the standard structure for the BJT and is in service today. The three of them were also awarded the Nobel Prize in Physics that year in 1956.

A transistor can simply be understood as a miniature switch. Depending on the properties of the semiconductor, an N-type semiconductor can be formed by doping the semiconductor with phosphorus and a P-type semiconductor with boron. The combination of N-type and P-type semiconductors forms the PN junction, an important structure in electronic chips; this allows specific logic operations to be performed (such as with-gates, or-gates, non-gates, etc.)

Germanium, however, has some very difficult problems, such as the many interface defects in the semiconductor, the poor thermal stability, and the lack of dense oxides. Moreover, germanium is a rare element, with only 7 parts per million in the earth's crust, and germanium ores are also very scattered. It is because germanium is very rare and not concentrated that the cost of raw materials for germanium remains high; things are rare, and the high cost of raw materials makes germanium transistors no cheaper, so it is difficult to produce germanium transistors on a large scale.

Researchers, therefore, jumped up a level and looked at the element silicon. You could say that all of the germanium's inherent deficiencies are silicon's inherent advantages.

Silicon is the second most abundant element after oxygen, but you basically can't find silicon monomers in nature; its most common compounds are silica and silicates. Of these, silica is in turn one of the main components of sand. In addition, compounds such as feldspar, granite, and quartz are all based on silica-oxygen compounds.

Silicon is thermally stable, has a dense, high dielectric constant oxide, and can easily be prepared with a silicon-silicon oxide interface with very few interfacial defects.

Silicon oxide is insoluble in water (germanium oxide is soluble in water) and insoluble in most acids, which is simply a perfect match for the corrosion printing technique used for printed circuit boards. The product of this combination is the flat process for integrated circuits that continues to this day.

Silicon crystal columns

Silicon's journey to the top

A failed venture: It is said that Shockley saw a huge market opportunity at a time when no one had yet succeeded in making a silicon transistor; that is why he left Bell Labs in 1956 to start his own company in California. Unfortunately, Shockley was not a good entrepreneur and his business management was a fool's errand compared to his academic skills. So Shockley himself did not fulfill the ambition of replacing germanium with silicon, and the stage for the rest of his life was the podium at Stanford University. A year after its founding, the eight talented young men he had recruited defected from him en masse, and it was the "eight traitors" who were to complete the ambition of replacing germanium with silicon.

The rise of the silicon transistor

Before the Eight Renegades founded Fairchild Semiconductor, germanium transistors were the dominant market for transistors, with nearly 30 million transistors manufactured in the United States in 1957, only one million silicon transistors and nearly 29 million germanium transistors. With a 20% market share, Texas Instruments became the giant in the transistor market.

Eight Renegades and Fairchild Semiconductor

The market's biggest customers, the US government and military, want to use the chips in large numbers in rockets and missiles, increasing the valuable launch load and improving the reliability of control terminals. But the transistors will also face harsh operating conditions caused by high temperatures and violent vibrations.

Germanium is the first to lose out when it comes to temperature: germanium transistors can withstand temperatures of only 80°C, while the military's requirements are for stable operation even at 200°C. Only silicon transistors can withstand this temperature.

The traditional silicon transistor

Fairchild invented the process of making silicon transistors, making them as simple and efficient as printed books and much cheaper than germanium transistors in terms of price. Fairchild's process for making silicon transistors is rough as follows.

Firstly, a layout is drawn by hand, sometimes so large that it takes up a wall, and then the drawing is photographed and reduced to a tiny translucent sheet, often with two lanes of three sheets, each representing a layer of circuitry.

Secondly, a layer of light-sensitive material is applied to the sliced and polished smooth silicon wafer, and the UV/laser is used to protect the circuit pattern from the transillumination sheet onto the silicon wafer.

Thirdly, areas and lines in the dark part of the transillumination sheet leave unexposed patterns on the silicon wafer; these unexposed patterns are cleaned with an acid solution, and either semiconductor impurities are added (diffusion technique) or metal conductors are plated.

Fourthly, repeating the three steps above for each translucent wafer, large numbers of transistors can be obtained on silicon wafers, which are cut by women workers under a microscope and then connected to wires, then packaged, tested, and sold.

With the silicon transistors available in large quantities, the eight renegade founders of Fairchild were among the companies that could stand alongside such giants as Texas Instruments.

The important push - Intel

It was the subsequent invention of the integrated circuit that summed up the dominance of germanium. At the time, there were two technology lines, one for integrated circuits on germanium chips from Texas Instruments and one for integrated circuits on silicon chips from Fairchild. At first, the two companies had a fierce dispute over the ownership of the patents on the integrated circuits, but later the Patent Office recognized the ownership of the patents on the integrated circuits by both companies.

However, as Fairchild's process was more advanced, it became the standard for integrated circuits and continues to be used today. Later, Noyce, the inventor of the integrated circuit, and Moore, the inventor of Moore's Law, left Centron Semiconductor, who, incidentally, were both members of the "Eight Traitors". Together with Grove, they created what is now the world's largest semiconductor chip company, Intel.

The three founders of Intel, from left: Grove, Noyce, and Moore

In subsequent developments, Intel pushed silicon chips. It has beaten such giants as Texas Instruments, Motorola, and IBM to become the king of the semiconductor storage and CPU sector.

As Intel became the dominant player in the industry, silicon also ended germanium, and what was once Santa Clara Valley was renamed "Silicon Valley". Since then, silicon chips have become the equivalent of semiconductor chips in public perception.

Germanium, however, has some very difficult problems to solve, such as the many interface defects of semiconductors, poor thermal stability, and the lack of dense oxides. Moreover, germanium is a rare element, with only 7 parts per million in the earth's crust, and germanium ores are also very scattered. It is because germanium is very rare and not concentrated that the cost of raw materials for germanium remains high; things are rare, and the high cost of raw materials makes germanium transistors no cheaper, so it is difficult to produce germanium transistors on a large scale.

Researchers, therefore, jumped up a level and looked at the element silicon. You could say that all of the germanium's inherent weaknesses are silicon's inherent strengths.

Silicon is the second most abundant element after oxygen, but you basically can't find silicon monomers in nature; its most common compounds are silica and silicates. Of these, silica is in turn one of the main components of sand. In addition, compounds such as feldspar, granite, and quartz are all based on silica-oxygen compounds.

Silicon is thermally stable, has a dense, high dielectric constant oxide, and can easily be prepared with a silicon-silicon oxide interface with very few interfacial defects.

Silicon oxide is insoluble in water (germanium oxide is soluble in water) and insoluble in most acids, which is simply a perfect match for the corrosion printing technique used for printed circuit boards. The product of this combination is the integrated circuit planar process that continues to this day.