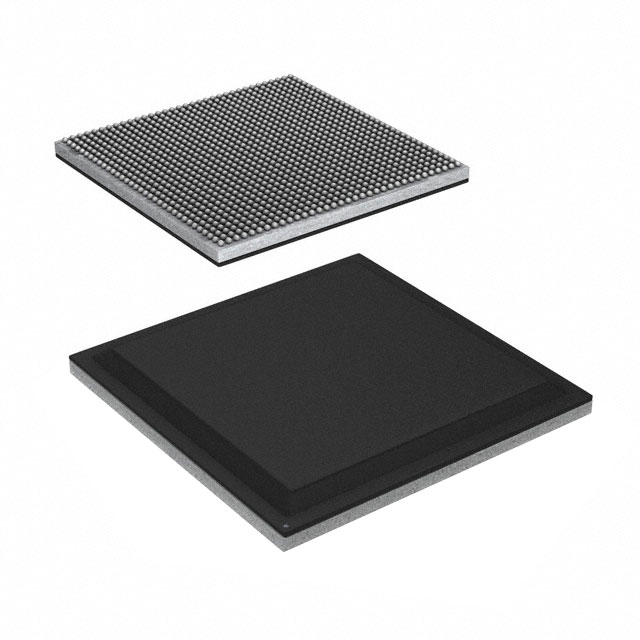

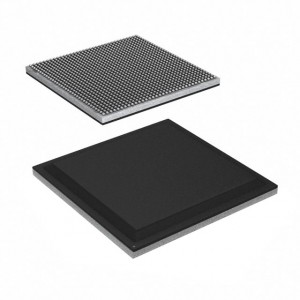

Original IC XCKU025-1FFVA1156I Chip Integrated Circuit IC FPGA 312 I/O 1156FCBGA

Product Attributes

|

TYPE |

ILLUSTRATE |

|

category |

Integrated Circuits (ICs) |

|

manufacturer |

|

|

series |

|

|

wrap |

bulk |

|

Product status |

Active |

|

DigiKey is programmable |

Not verified |

|

LAB/CLB number |

18180 |

|

Number of logic elements/units |

318150 |

|

Total number of RAM bits |

13004800 |

|

Number of I/Os |

312 |

|

Voltage - Power supply |

0.922V ~ 0.979V |

|

Installation type |

|

|

Operating temperature |

-40°C ~ 100°C (TJ) |

|

Package/Housing |

|

|

Vendor component encapsulation |

1156-FCBGA (35x35) |

|

Product master number |

Documents & Media

|

RESOURCE TYPE |

LINK |

|

Datasheet |

|

|

Environmental information |

Xiliinx RoHS Cert |

|

PCN design/specification |

Classification of environmental and export specifications

|

ATTRIBUTE |

ILLUSTRATE |

|

RoHS status |

Compliant with the ROHS3 directive |

|

Humidity Sensitivity Level (MSL) |

4 (72 hours) |

|

REACH status |

Not subject to the REACH specification |

|

ECCN |

3A991D |

|

HTSUS |

8542.39.0001 |

Product Introduction

FCBGA(Flip Chip Ball Grid Array) stands for "flip chip ball grid Array".

FC-BGA(Flip Chip Ball Grid Array), which is called flip chip ball grid array package format, is also the most important package format for graphics acceleration chips at present. This packaging technology began in the 1960s, when IBM developed the so-called C4(Controlled Collapse Chip Connection) technology for the assembly of large computers, and then further developed to use the surface tension of the molten bulge to support the weight of the chip and control the height of the bulge. And become the development direction of flip technology.

What are the advantages of FC-BGA?

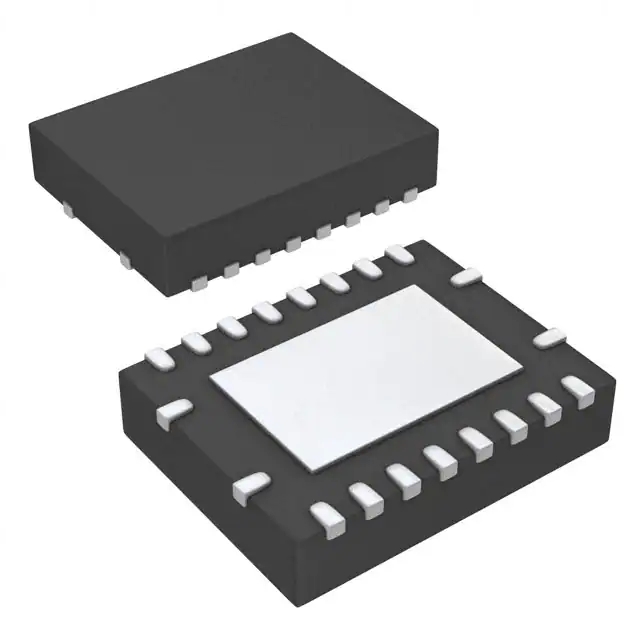

First, it solves electromagnetic compatibility (EMC) and electromagnetic interference (EMI) problems. Generally speaking, the signal transmission of the chip using WireBond packaging technology is carried out through a metal wire with a certain length. In the case of high frequency, this method will produce the so-called impedance effect, forming an obstacle on the signal route. However, FC-BGA uses pellets instead of pins to connect the processor. This package uses a total of 479 balls, but each has a diameter of 0.78 mm, which provides the shortest external connection distance. Using this package not only provides excellent electrical performance, but also reduces the loss and inductance between component interconnects, reduces the problem of electromagnetic interference, and can withstand higher frequencies, breaking the overclocking limit becomes possible.

Second, as display chip designers embed more and more dense circuits in the same silicon crystal area, the number of input and output terminals and pins will increase rapidly, and another advantage of FC-BGA is that it can increase the density of I/O. Generally speaking, the I/O leads using WireBond technology are arranged around the chip, but after the FC-BGA package, the I/O leads can be arranged in an array on the surface of the chip, providing a higher density I/O layout, resulting in the best use efficiency, and because of this advantage. Inversion technology reduces the area by 30% to 60% compared to traditional packaging forms.

Finally, in the new generation of high-speed, highly integrated display chips, the problem of heat dissipation will be a big challenge. Based on the unique flip package form of FC-BGA, the back of the chip can be exposed to air and can directly dissipate heat. At the same time, the substrate can also improve the heat dissipation efficiency through the metal layer, or install a metal heat sink on the back of the chip, further strengthen the heat dissipation ability of the chip, and greatly improve the stability of the chip at high-speed operation.

Due to the advantages of FC-BGA package, almost all graphics acceleration card chips are packaged with FC-BGA.